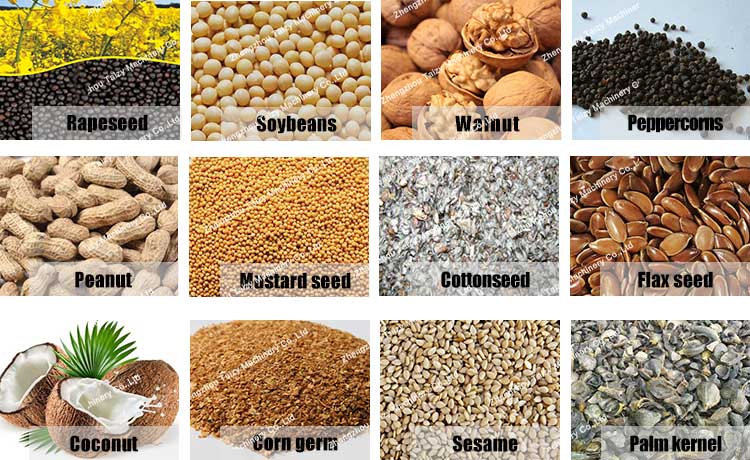

The screw oil press is a type of automatic oil extraction machine, which mainly squeezes out the oil through a screw. The oil screw press output is very extensive. It is not only suitable for small households but also suitable for large oil mills. The screw press oil extractor can be used to squeeze out almost all raw seeds and nuts, including peanuts, soybeans, rapeseed/canola, sesame, coconut, palm kernel, corn, hemp, flaxseed, sunflower seed, canola seed, baobab seed, cottonseed, and other materials. The screw press machine for oil extraction has an automatic temperature control function. The extracted oil tastes good, and the oil yield is high. We are an experienced oil mill machine manufacturer. Our screw oil extractors are very popular in the international oil press market and have been exported to many countries, like America, Australia, Germany, Iran, Mexico, Philippines, Nigeria, Kenya, etc.

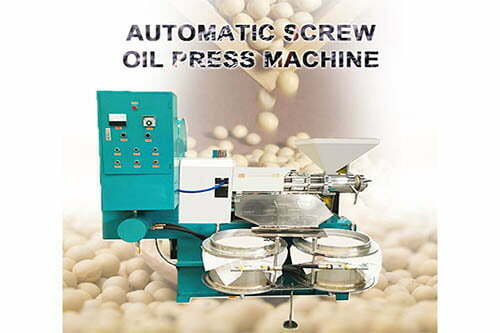

Introduction of screw oil press machine

The commercial screw oil press machine can press sesame, walnuts, peanuts, olives, soybeans, cocoa beans, pine nuts, sunflower seeds, almonds, and other high oil crops.

This screw press oil extraction machine is the latest domestic small and medium-sized oil press equipment developed by the company through long-term production. It adopts a multi-stage pressing and oil filtering system, including a centrifugal oil filter, or a vacuum oil filter barrel, which makes the purification of the crude edible oil fast, and realizes the low-temperature pressing.

Screw press oil extractor working principle

When connecting the power, the power unit of the screw oil extractor drives the screw on the main shaft to rotate. The screw press continues to rotate, so the raw material in the squeeze chamber continues to move forward. The farther forward, the gap between the pressing chamber and the pressing screw gradually gets smaller, and the oil density and the pressure increase. At the same time, the friction between the oil and the spare part produces a lot of heat.

The huge pressure and a lot of heat destroy the oil cells, and the oil overflows from the oil line. The spilled oil passes through the oil pan and falls onto the oil filtering cloth. Filtered by the oilcloth on the vacuum filter oil drum, it obtains relatively pure oil. After extracting by the screw oil press, it produces oil cakes, and the oil cakes are extruded at the outlet.

Industrial screw type oil expeller structure

The screw oil expeller machine mainly comprises five parts: the electrical control part, the heating and pressing part, the adjustment part, the transmission part, and the vacuum oil filtering equipment.

The electrical control part is mainly used to control the operation of the entire oil expeller machine.

The heating and pressing part composes of heaters, squeezers, and body devices.

The adjusting part is composed of adjusting screw, adjusting nut, handle, lock nut, and so on. This part can be used to adjust the pressing pressure and the thickness of the pressed oil cake.

The transmission part composes of the main shaft, a gearbox, a pulley, and a motor wheel.

The vacuum oil filtering system is mainly used to filter impurities in the oil. The system is mainly composed of a vacuum pump, oil filtering cloth, barrel, pipeline, etc.

Feature of screw oil press

1. High oil extraction ratio. Low residual oil ratio in the dry oil cakes. The screw oil extractor can squeeze out the oil in the raw material to the greatest extent. The automatic oil press improves the oil yield.

2. High-efficient production. The vacuum oil filtering system ensures that the oil pressing and filtering at the same time, which improves the production efficiency of oil squeezing.

3. Easy to operate and reasonable design.

4. Wide application. The screw oil pressing machine is a combination of cold pressing and hot pressing. Therefore, it widely applies in the extraction of various raw materials.

5. Diverse outputs are available. There is a variety of machines with different outputs to choose from. The oil press machinery reduces the cost and meets the individual’s demand for oil squeezing.

Technical Parameter

| Model | TZ-60A | TZ-70A | TZ-80A | TZ-100A | TZ-125A | TZ-150A |

| Screw diameter | 60mm | 70mm | 80mm | 100mm | 125mm | 150mm |

| Capacity(kg/h) | 30-60 | 50-80 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor | 2.2kw | 5.5kw | 5.5kw | 7.5kw | 15kw | 22kw |

| weight (kg) | 220 | 350 | 700 | 1100 | 1400 | 1700 |

| Size(mm) | 1280*630*1370 | 1480*630*1570 | 1480*630*1570 | 2200*810*1850 | 2200*1650*1750 | 2600*2100*1730 |

Automatic oil expeller work process

- First, according to different raw materials, selectively shell the raw materials;

- Before starting up, check whether the various parts of the machine are loose. Rotate the pulley by hand to avoid abnormal noise. Then add mechanical oil to the gearbox.

- Adjust the screw to make the conical surface of the squeezing screw press against the conical surface of the cake outlet. Adjust the screw clockwise by 2~3mm, and then tighten the nut.

- Connect the power supply and turn on the power switch of the screw press.

- Adjust the temperature controller through the electrical control panel of the oil expeller machine. Adjust the suitable temperature (150~200 Celsius degrees) according to the oil raw material characteristics. When the screw oil press machine temperature reaches the set temperature, the green indicator light is off and the red indicator light is on.

- Rotate the main unit button, and the main unit starts to run. The rotation direction of the screw shaft should be counterclockwise.

- Put the processed material at the inlet of the screw oil expeller, and the screw press pushes the material forward and squeezes out the oil.

- When the squeezed oil flows to the oil filter barrel, turn on the filter switch of the oil filter barrel. After completing the oil filtering, turn on the switch under the oil filter barrel to release the filtered oil.

How to maintain the oil screw pressing machinery?

- After the machine has run for 50 hours, check whether there is still lubricating oil in the oil cup on the gearbox. Add oil to the screw hole of the screw bearing before pressing oil each time. Dry grinding is strictly prohibited.

- After each oil extraction, clean up the remaining oil cakes in the oil screw press machine. And remove the dust and grease on the surface of the machine.

- When the oil extraction or the cake is abnormal, take out the screw shaft to check the wear of screw, strip and cake ring, and replace the worn parts in time.

- If you do not need to use the machine for a long time, clean the screw oil press and place it in a dry and ventilated place. Take out the pressing screws, pressing strips, and cake rings. Then, clean and grease them, and place them in a cool place.

Video of screw oil expeller

FAQ

Can the temperature of the screw oil press be adjusted?

Yes, there is a control panel for adjustment.

What are the applicable raw materials for the screw oil extractor?

Coconut powder, peanut, rapeseed, soybean, hemp, sesame, flax seed, corn germ, melon seed.

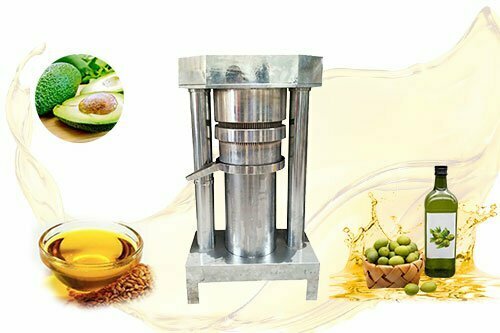

Do you use a screw oil expeller for sesame?

Yes, it can do, but the hydraulic type has a better effect with a higher oil yield.

What kind of oil extractor does the baobab tree use?

Screw oil press.

What are the vulnerable parts of a screw oil extractor?

The machine works stably. The main vulnerable part is the screw shaft.

The oil yield of hot pressing is higher than that of cold pressing, isn’t it?

Yes.

What is the general length of the screw shaft?

60,70,80,100,125,150mm

Are the parts contacting materials made of stainless steel?

Yes.

What is the output range of the screw oil expeller?

30-600kg/h

Is the material for pressing wet or dry?

Generally, it is dry.

How many oil filters do the oil extraction machine comes with?

1

How many oil filter barrels are equipped with screw oil press machinery?

2

Other applications

Factors affecting oil yield

Generally, the oil yield of a screw oil press is directly related to the oil content and the pretreatment of raw materials, oil extraction methods, and operation methods, etc. There are many factors affecting oil yield.

Another type of oil press machine

Oil filter machine